Dalgakıran Solar Power Plant Success Story

About Dalgakıran Compressor

Dalgakıran Compressor, Turkey’s largest industrial compressor manufacturer and exporter, was founded in 1965 by Ömer Dalgakıran in a modest 25 m² workshop in Istanbul. Since its establishment, the company has grown rapidly through continuous investments and today operates a production facility spanning more than 70,000 m².

As one of Turkey’s top 500 exporters, Dalgakıran reliably exports compressors to over 130 countries worldwide, while continuing to invest, grow, and contribute to the development of both industry and the economy.

With over 60 years of experience, a dynamic team, and a commitment to customer satisfaction in an increasingly globalized market, Dalgakıran serves clients across the world through more than 150 dealers, branches, and an extensive service network.

About the Project

A field study was conducted at Dalgakıran’s rooftop solar power plant in the Marmara Region to demonstrate the impact of panel cleaning on both energy generation and economic performance. As part of the study, only one group of panels connected to a designated test inverter was cleaned using a robotic method. Production and thermal data were meticulously analyzed before and after cleaning.

The Challenge

Dust, bird droppings, dirt, and other particles accumulating on the surface of solar panels block sunlight, reducing energy production.

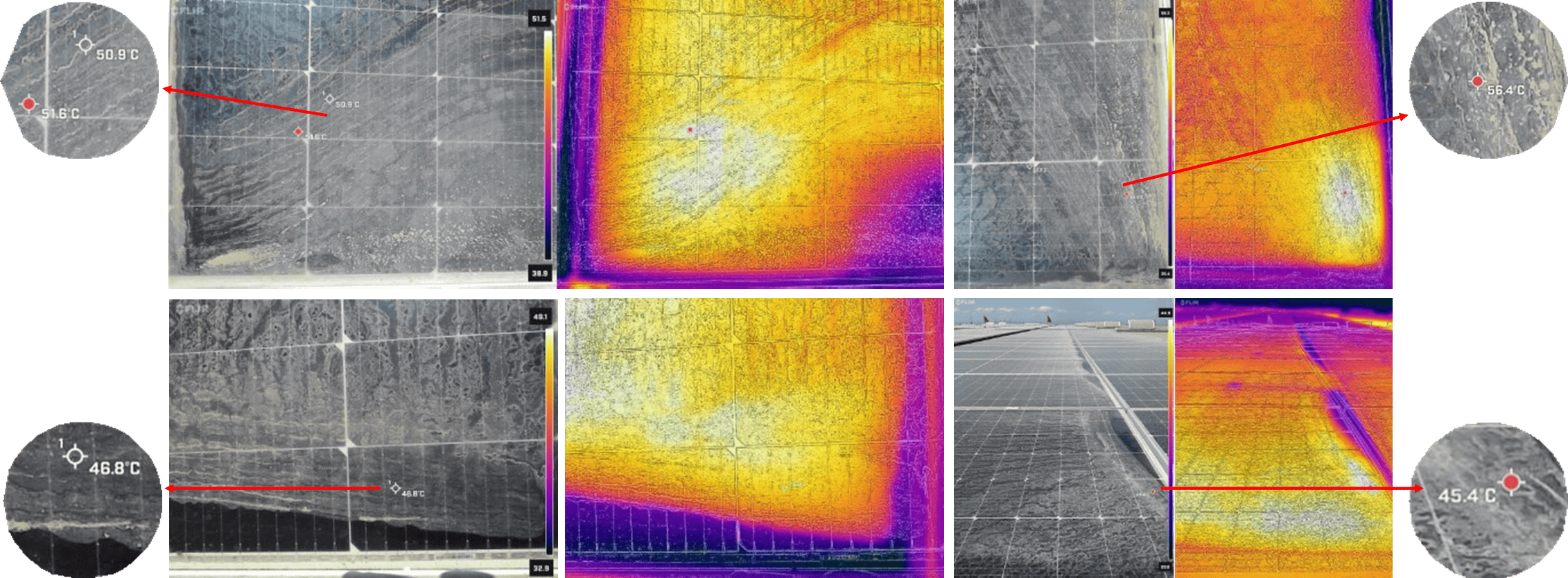

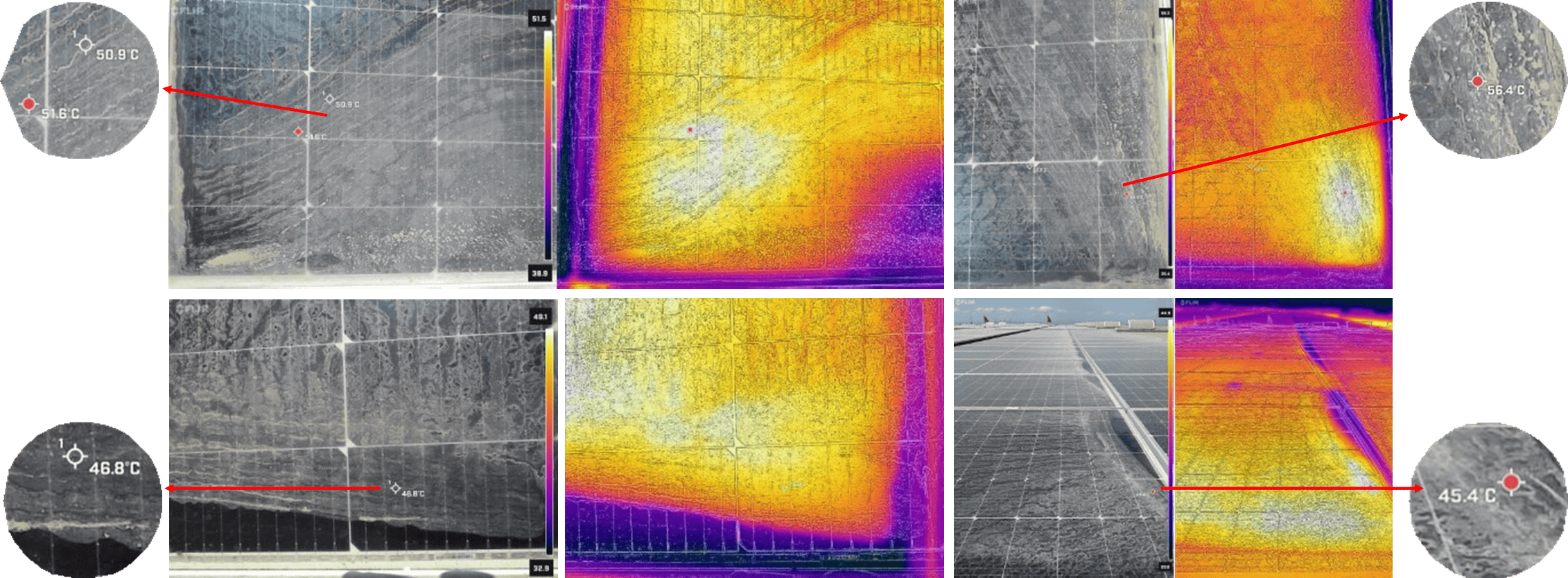

Thermal imaging taken before cleaning showed that dirty panel areas reached surface temperatures as high as 55–60 °C. This demonstrated that dirt was obstructing irradiation absorption, leading to thermal asymmetry and performance losses.

Energy production data clearly revealed the impact of soiling: the test inverter connected to dirty panels produced significantly less compared to reference inverters, with the performance gap becoming more apparent during peak sunlight hours.

If cleaned manually, the main difficulties and risks would have included:

- Hundreds of hours of intensive labor

- High water consumption

- Human error and risk of damage to panel surfaces

- Significant occupational health and safety risks (due to high rooftops and sloped surfaces)

- Challenges in operational planning and coordination

The Solution

Using the Robsys RTM Pro product, the robotic cleaning system efficiently cleaned the solar panel surfaces with specially designed brushes and controlled pressure, consuming minimal water. This technology ensured the effective removal of dirt, improving both panel performance and energy output.

Key Benefits of Robsys Robotic Cleaning Systems:

• Speed and Efficiency

The robotic method was approximately 8–12 times faster compared to manual cleaning.

• Safety

Because the cleaning robots were remotely operated, the need for personnel to work at heights was minimized. As a result, occupational safety risks and related operational costs were reduced.

• Water Efficiency

The robots used targeted and controlled water application, consuming 60–70% less water than manual cleaning. This not only lowered costs but also provided a significant environmental advantage by conserving natural resources.

• Quality and Panel Protection

Robots were equipped with specially designed brushes and adjustable pressure settings to avoid damaging panel surfaces. Thanks to these features, the risk of micro-scratches was significantly reduced. Robotic cleaning ensured safe, damage-free cleaning while also enabling more consistent maintenance planning, helping panels operate efficiently for many years.

• Cost-Effectiveness

Although requiring an initial investment, robotic cleaning systems delivered substantial long-term savings in labor, water, and operational expenses.

The Results

• Increased Energy Production

After cleaning, the test inverter produced approximately 15–25% more energy compared to the reference inverters left uncleaned on the same day.

• Improved Thermal Performance

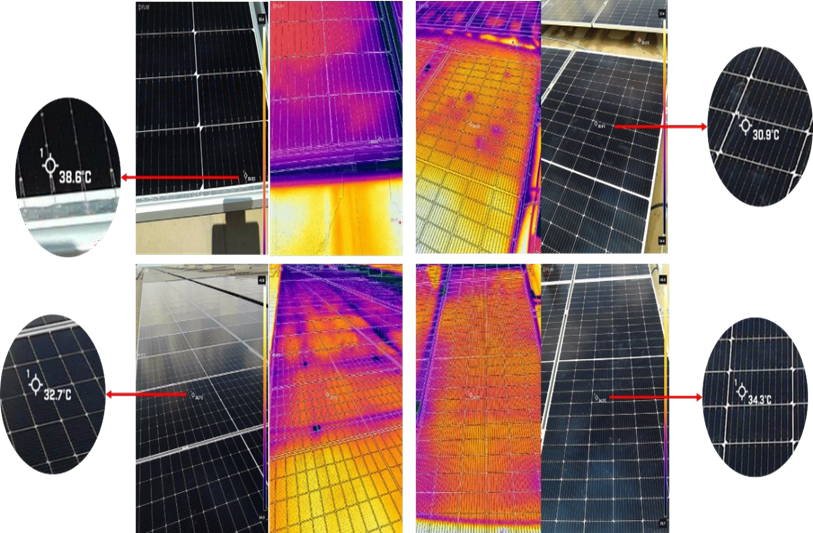

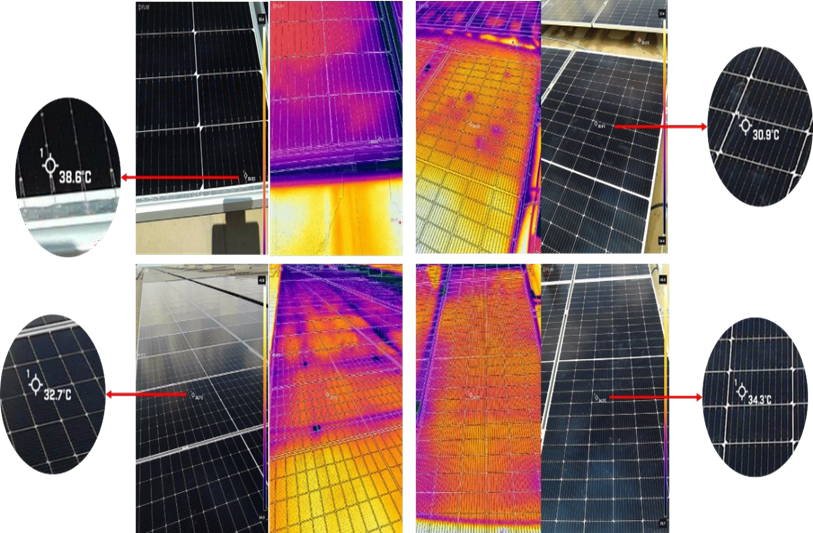

Panel surface temperatures dropped by around 25–30% after cleaning. This indicated that the removal of dirt reduced irradiation blockage and allowed the panels to cool more effectively.

Thermal Images Taken Before Cleaning

Thermal Images Taken from the Field After the Cleaning Process

• Economic Impact

On an annual basis, the project enabled additional energy production measured in the hundreds of thousands of kWh, resulting in significant extra revenue.• Cost Savings

Compared to manual cleaning, robotic cleaning systems provided operational savings amounting to millions of Turkish Lira annually.• Return on Investment

When both energy gains and operational savings were considered, the investment generated meaningful net returns each year. The system typically paid for itself in around two years, after which investors enjoyed substantial net profit.