About Project:

Project Capacity: 5 MW

Project Location: Dilovası OSB / Türkiye

Product Used: RTM PRO

Project Type Rooftop

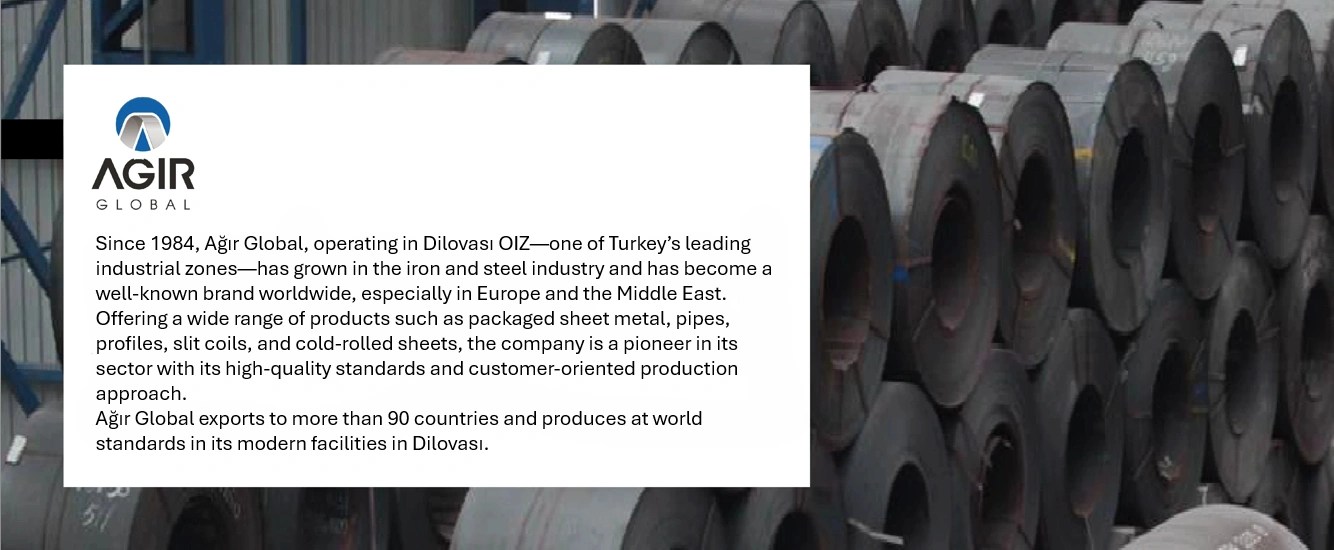

About Ağır Global:

Operating since 1984 in the Dilovası Organized Industrial Zone, one of Turkey’s leading industrial regions, Ağır Global has grown steadily in the iron and steel industry and has become a globally recognized brand, especially across Europe and the Middle East.

Offering a wide range of products including bundled sheets, pipes, profiles, slit strips, and cold-pressed sheets, the company stands out with its high-quality standards and customer-focused production approach.

Today, Ağır Global exports to over 90 countries and manufactures at international standards in its modern facilities in Dilovası.

Problem / Opportunity

Due to intensive industrial operations and steel production at its Kocaeli facility, Ağır Global began facing significant performance losses in its PV system, caused by the accumulation of industrial dust, metal particles, smoke residues, and natural pollutants (such as pollen and bird droppings) on panel surfaces.

As part of its sustainability goals, the company aimed to use energy more efficiently and reduce its carbon emissions. However, traditional cleaning methods proved inadequate. Panel cleaning processes outsourced to third parties became unsustainable, and safety risks due to manual labor further complicated the issue. Consequently, Ağır Global decided to invest in robotic cleaning technology.

Solution:

To prevent the 5% production loss experienced in its 5 MW rooftop solar power plant and to ensure sustainable energy generation, Ağır Global invested in Robsys-brand robotic PV cleaning systems, which are locally manufactured.

Equipped with special brushes that clean without damaging panel surfaces and capable of operating safely even on inclined rooftops, these robots completely eliminated the need for manual cleaning and provided a safe, high-standard cleaning solution.

Through this investment, Ağır Global not only ensured continuity in energy production but also contributed to its environmental targets by reducing carbon emissions.

Output:

The system compensated for the 5% production loss due to soiling in its very first year, achieving return on investment in approximately 18 months.

The factory reduced its energy costs by 60% while also minimizing maintenance and occupational safety expenses. Additionally, it began generating extra income by selling surplus energy on sunny days.

“The system we acquired prevented a 5% production loss in the very first year and paid for itself in just 18 months.”

– Levent Çerezci, CFO, Ağır Global